If for some reason you need to pump fine dust dust or a fluid (gas or liquid) without it flowing through the pump itself, Venturi is a great way to go. Two good examples are wood or fiberglass dust collection, as sucking these through the pump would result in gunk accumulating inside the diaphragm/fan and bearings and damage the operation of the pump.

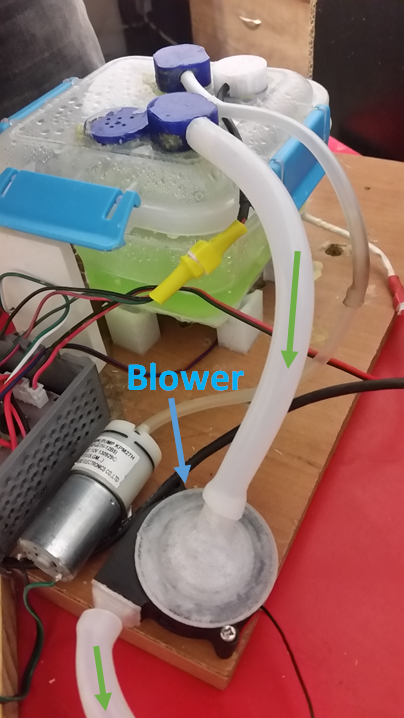

My motivation in making a Venturi pump originated from a PCB etching station I’m working on. It is filled a cupric chloride solution and upon heating, some chlorine gas is evaporated. The gas is quite nasty to breath, it is heavier than air and sinks below the window level, therefore does not evacuate without sufficient air flow through the room.

My initial solution was very naive, I was pumping the chlorine gas right through a generic PC blower and it did not last more than several hours of work. The chlorine gas condensed in the motor housing and corroded it to its death.

I then decided to use a Venturi pump to suck the chlorine fumes without them flowing through the blower, and went on by searching models online that design for 3D printing. Unsurprisingly I was unable to find a customizable model in Thingiverse as designers usually upload STLs only, without including the MCAD source files, so I went on and designed a Venturi pump from scratch, using the following concept:

The main principle here is that by generating air flow through a narrow throat, the fluid accelerates to a higher speed and by conservation of energy the pressure must drop, as seen in the Bernoulli equation:

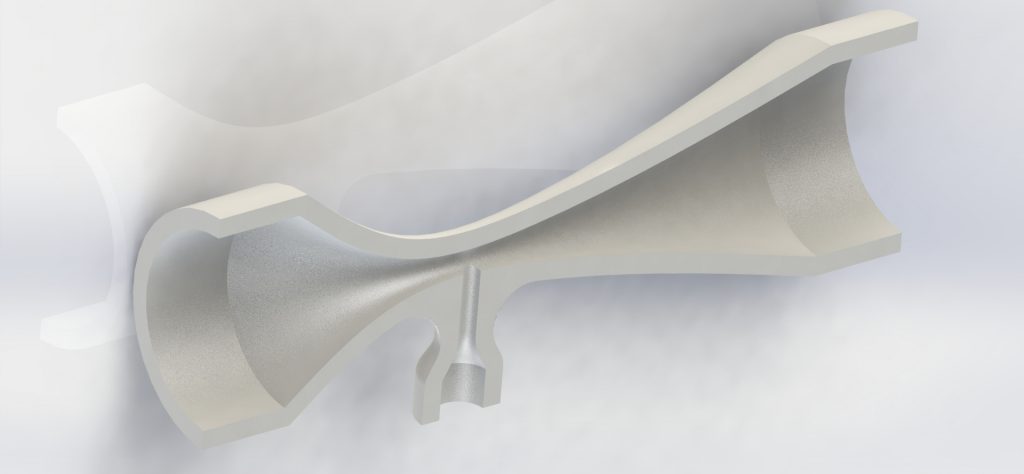

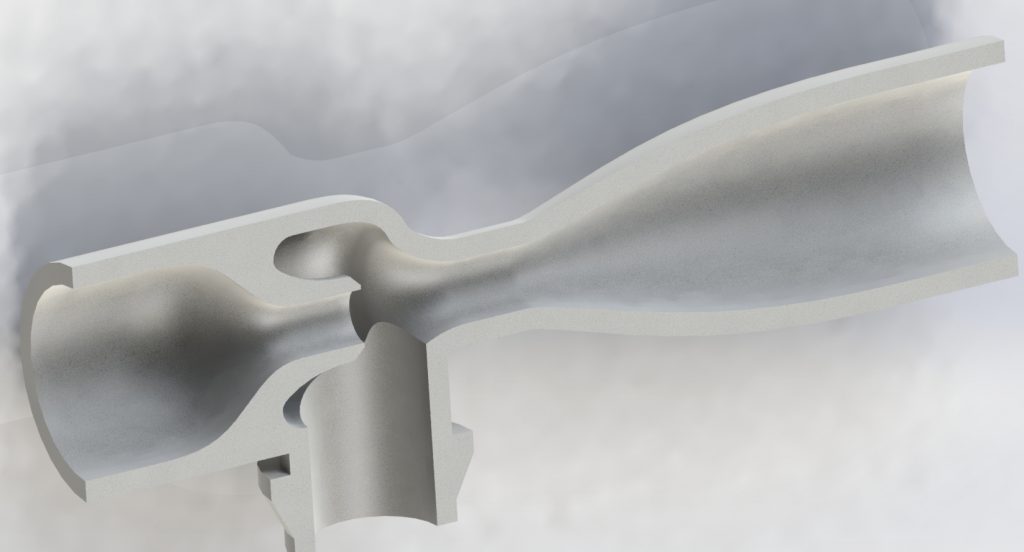

By adding an air inlet in the throat, we can tap into the pressure drop and suck air into the main stream (if the air velocity is high enough to drop the pressure in the throat below atmospheric pressure). Turning this idea into a Solidworks model was quite easy:

Sadly, when I blew air through the device, the suction inlet was actually blowing the air out! I’ve tried several throat sized and configurations to no avail, they all suffered from the same phenomenon. one possible explanation is that the Bernoulli equation does not hold for compressible fluids such as air.

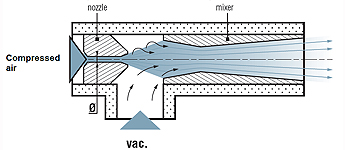

I was very disappointed and went back to searching online for Venturi designs, and noticed that almost all of the Venturi devices shaped this way are designed for water as the main channel fluid. I also found out that popular design for air powered Venturi pump is the following:

As I have never studied fluid mechanics, I can only guess why this design works well for airflow, and I think that the air exiting the the nozzle moves forward so fast that it does not curve into the vacuum port, thus not adding to its pressure, and at the same time, it pushes on the fluid in the expansion chamber, and creates a drag force sucking air through the vacuum port.

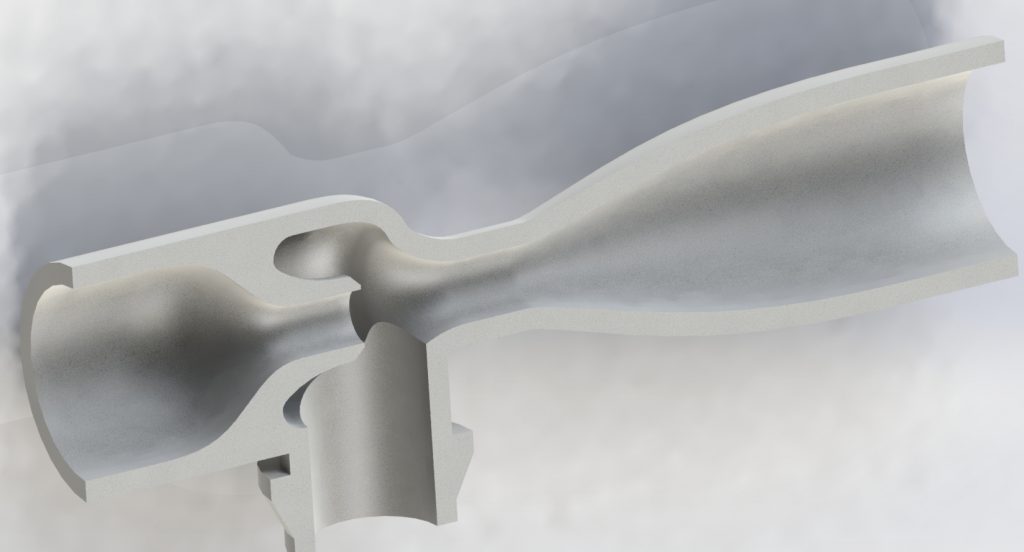

I then modeled the concept into a 3D model:

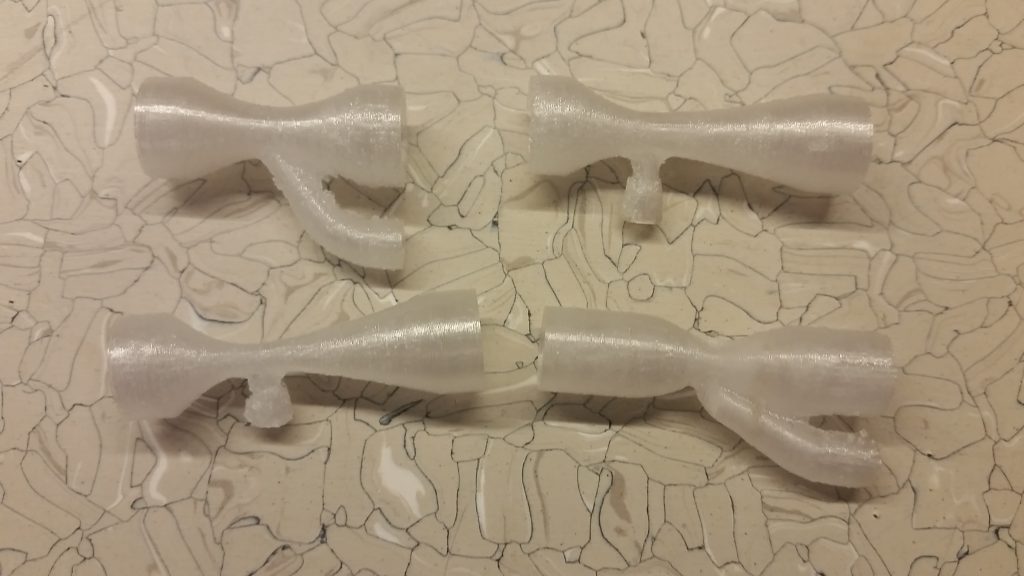

3D printed it (it’s not pretty, I own a 3 year old Printrbot, so sew me):

and… SUCCESS!!! I was able to lift small pieces of paper with, and that made me unproportionally happy! But then I felt that sharing measurable numbers is a bit more informative than paper lifting, and decided to measure the static vacuum pressure and the unobstructed (no load) flow rate.

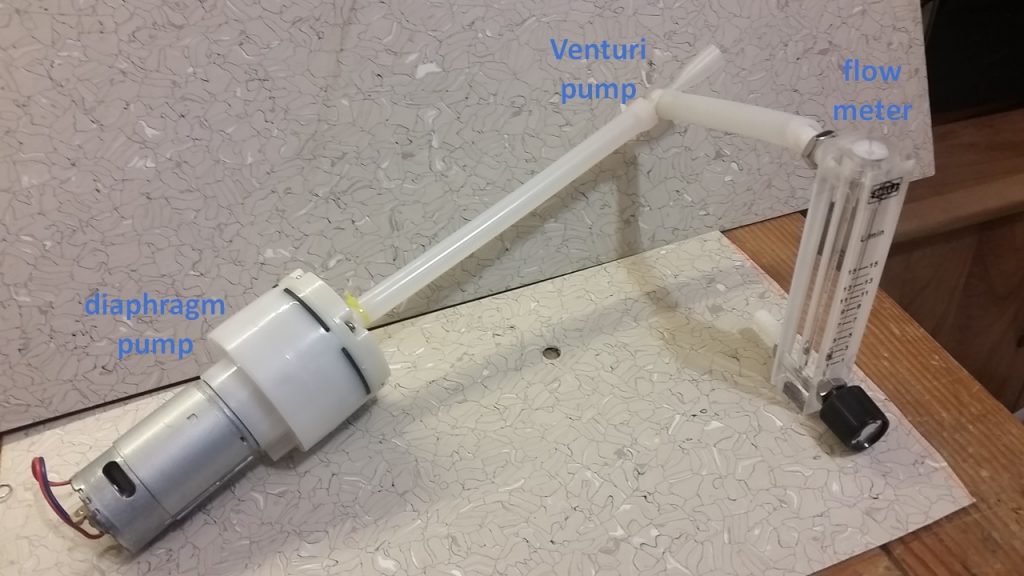

First I made a setup to measure the flow rate using a diaphragm pump, a flow meter, and the Venturi pump:

And measured the flow rate through the vacuum port to be almost 1.5 L/min. I have also measured the flow through the main channel of the venturi to be 10 L/min.

I proceeded with measuring the static vacuum pressure by immersing a hose from the suction port and into a water cup and measuring the water rise to be 9 cm, which correlates to 0.01 Bar.

Playing with the Venturi pump, I also made a gif showing a candle flame being sucked into a glass tube:

In conclusion, I can now safely exhaust any nasty chemical out without damaging the exhaust! In case anyone else is interested in making their own Venturi for whatever use, I am sharing my model in GrabCAD.

I am by no mean a specialist in fluid dynamics, and I am sure that my design is far from optimal, and I hope that this blog post will inspire someone who is more educated on the subject to make a superior design made ready for 3D printing for public use.

Pingback: A Crash Course In 3D Printed Venturi Pumps

Hi, a couple of things you might consider. #1 max vacuum will occur at max airspeed, which is at smallest cross-section of the venturi – so put the suction inlet in the smallest part of the venturi, not before it. #2 vacuum is related to fluid speed (square-root of, I guess) so inlet air will have to flow very fast to get much vacuum pressure. All the best, nice project.

Pingback: A Crash Course In 3D Printed Venturi Pumps - 3DPrinter.News

Pingback: A Crash Course In 3D Printed Venturi Pumps - FeedBox

Hi,

First, awesome project! It’s so cool what geometry 3d printing enables that was completely out of reach of hobbyists!

Second if you’re interested I can run some fluid simulations on the design that you created and maybe give you some feedback on what may be able to improve it (improving suction pressure, suction flow rate, outlet pressure resilience). One of my projects this year at school involved creating 3d printed venturi pumps for injecting powders. I’m by no means an expert at fluids either, but your conclusion about your initials designs having a problem with compressible flow feels right to me.

All the best

~Max

Hello, this is Cristian from Mexico.

I’m looking for a designd to help to COVID-19 sanitize places, inputs are a water hose and

a soda bottle with chlorine.

Result need to be a pulverized solution with 90% water and 10% clorine.

You are in the right way, and i need to re do all your steps and errors.

This device may help to all people to sanitize your places, packages, transports, and all other needed

with only put a water hose and a soda bottle with chlorine.

Can you work on this? if you need some money please write to my email.

Thank you, regards

Cristian

RL Flo-Master Chameleon Hose End Sprayer

Chlorine is caustic

Try http://www.steramist.com

i don’t understand why